Why Does The Aerosol Valve Leak?

4 Tips You Should Know Using DME As The Aerosol Propellant

July 22, 2019

3 Aerosol Insecticide Solvents You Should Know Before Starting The Business

August 30, 2019 Aerosol Valve

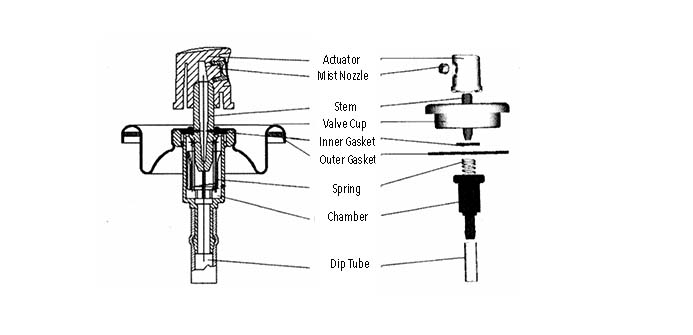

Aerosol ValveAs an important part of the aerosol product package, aerosol valves have the leakage potential under the pressure inside the aerosol can.

Here the leakage refers to the abnormal leaking phenomenon that obviously overpasses normal condition.

Hereby, the valve leakage refers to the leaking phenomenon of contents or propellant gases through the gap between each component of the valve(see below image).

aerosol valve cross image

Leakage can result in aerosol product’s malfunction.

- All contents and propellant gases are leaked out of the aerosol can.

- Only a portion of the contents can be sprayed out. The remains can’t be repelled out.

- The contents can’t be sprayed out at all.

As long as the above issues occur, the consumer’s confidence in the content and repeated buying desire is seriously weakened.

One of the causes come from the aerosol valve quality.

Leakage Type

In order to better analyze the aerosol valve leakage cause, we usually differentiate leakage types from the leaking time.

And usually, there are 2 types: dynamic leakage and static leakage.

Dynamic Leakage

As the valve is in open condition, the contents are sprayed out through the unexpected channel to leak. And this leakage is dynamic type.

Static Leakage

As the valve is in a closed condition, the contents are leaked abnormally. And this leakage is caused by the valve itself.

Leakage Cause

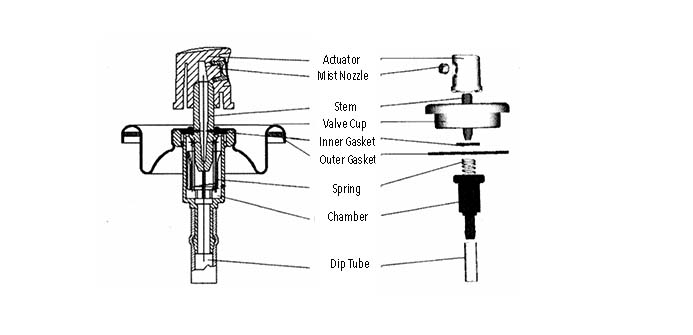

Refer to the image below.

Dynamic Leakage Locations and Causes

1) Leakage happens between the stem and actuator. The contents are leaked in the conjunction of the stem and actuator sealing area during spraying. The causes include below.

- The stem and actuator sizes are not matched to achieve sealing;

- There is crack at the connection area of the actuator and the stem;

- The connection area of the actuator and the stem swells due to the contents to lead to non-tight sealing;

- In the use of spray-through cap, the cap and the stem are not homocentric, so there is a certain angle as touching to lead to leakage;

- The upper part of the stem is not qualified for molding injection, for example, not enough injection, crack, ect.

2) Leakage between the stem and the inner gasket. The contents are leaked in the contacting area of the stem and the inner gasket. The reasons include below:

- The inner gasket inside the circle is broken, which can’t cover the stem completely and tightly;

- The stem surface is rough and ragged, unable to be completely covered by the inner gasket;

- There is impurity between the inner gasket and the stem, so they can’t be sealed tightly.

3) Leakage between the valve cup and the inner gasket.

- The valve cup deformed, and the contacting part with the inner gasket is not tight enough;

- The upper surface of the inner gasket is not even, failing to touch tightly with the valve cup;

- The valve pressing the inner gasket not enough, influencing the tightness between the inner gasket and the valve cup.

4) Methods to test valve leakage locations

We should evaluate and judge the leakage type and location as we receive customer’s complaints on the valve leakage.

- Observe or test the valve leakage condition(when minor slight leakage happens) at a static situation. If the abnormal leakage occurs, that means static leakage result is correct.

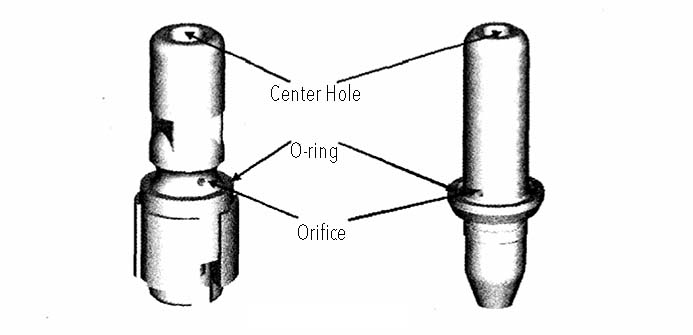

- When observing dynamic leakage, we need to block the stem center hole to prevent the contents from spraying out. In such a case, an actuator with a blind hole is applied usually. Observe the valve leakage condition when the valve is open. If the leakage is visible, it is the dynamic leakage.

Usually, if the valve dynamic slight leakage exits(hard to test), basically it can be ignored because the valve can open not a too long time. This slight leakage influences very little on the contents use.

There are 3 areas for the aerosol valve leakage: stem center hole, between stem and inner gasket, between valve cup and gasket. The methods to distinguish them as below.

- It’s obvious and visible for the stem center hole leakage. Usually, there is a liquid or bubble coming out from there.

- If observing from the outlook, they are the same area point for the other 2 cases. The difference is that if the leakage is from between the stem and the inner gasket, the leakage should be a liquid and propellant gas mixture. Because the whole channel for this leakage is can bottom – dip tube – valve chamber – valve stem/gasket.

But, if the leakage is only propellant gas, then it can be ensured that it comes from between the valve cup and the inner gasket. The leakage channel is can top(vapor area) – valve cup/gasket.

How to tell the leakage is the mixture of the liquid and propellant gas?

The easy way is to observe if any liquid residue because propellant gas vaporizes very soon and it belongs to the mixture if there is residue.

Conclusion

Valve leakage is a complicated topic because there are up to a dozen of components in the valve. There are many sealing points, any part can influence the performance.

It’s a professional and complex process for aerosol valve analysis. Above is just some simple methods.

It has to be pointed out that there are many causes for the leakage. It can be the quality issue in valve design and production, or it can also be the aerosol contents corroding the valve components, especially the gaskets. So, in aerosol production development, contents should also be considered seriously.