How much do you know about aerosols and their production filling equipment?

What are the standards for the production of aerosol cosmetics?

December 13, 2019How to design aerosol filling fire fighting workshop

September 14, 2020Speaking of aerosols, everyone may be confused. However, self-painting, pesticides and other aerosols commonly used in daily life are not unfamiliar to everyone, because of its convenient use, sealed and long shelf life, direct and effective role, it is increasingly welcomed by consumers.

Aerosols started in Norway in the early 1930s. During World War II, the US military abroad first applied insecticidal aerosols to drive off mosquitoes and flies. In 1945, the United States switched insecticide aerosols from military to civilian and put them on the market for public sale. In 1946, there was only one insecticide aerosol in the US market. Two years later, indoor disinfection aerosols and automotive aerosols were added. Subsequently, various medical aerosols continued to appear on the international market. In the 1970s, there were about 60 countries producing aerosols abroad. In recent years, due to the continuous development of science and technology, the application range of aerosol products has become wider and wider, and the variety has increased. The scope of application of aerosols has expanded to various fields, and has entered millions of households worldwide. The agent product manufacturing industry has become a major industry for industrial and civilian use in various countries.

In the early 1980s, insecticide aerosols that had just been put on the market, hair mousse aerosol products were generally welcomed by the people, and the needs of the society promoted the vigorous development of the aerosol-like industry. China’s aerosol output increased from about 30 million bottles in the mid-1980s to about 560 million bottles in 2000, an increase of more than 18 times in 15 years, and the speed of growth is amazing. However, from the perspective of per capita consumption, the annual per capita consumption of all people is only about 0.43 bottles, ranking second to last in the world. This statistic sleep aerosol technology station in China has great potential and is excellent for domestic aerosol companies opportunity. According to data provided by the Chinese Aerosol Professional Committee, in 2015, 15.63 billion cans of aerosol products were produced globally, and the market size reached 100 billion US dollars. China produced 2.05 billion cans of aerosol products in 2016, with an average annual growth rate of more than 10%. The Chinese market has developed into the third largest producer in the world after Europe and the United States.

So how do aerosol products produce bottling? It’s very simple, you only need to complete the three basic steps of filling the original liquid, sealing, and filling the propellant. Equipment selection According to the actual situation, according to the budget and production volume, select the appropriate air freshener filling equipment.

For the first-time start-ups, there is a small three-in-one aerosol filling machine, which is composed of a liquid filling machine, a sealing machine, and a propellant gas filling machine. Its liquid filling, sealing and inflating head is fixed on a workbench, using a booster pump can work more stable and safer. In addition, the machine has a small footprint and simple operation, and can be sealed and filled with propellant with only one worker.

There are also medium-sized filling machines. The machine is composed of a bottle unscrambler table, a full-automatic filling machine, an automatic valve loading machine, an automatic sealing inflator, an automatic nozzle machine, an automatic capping machine, and a packing box. The degree of automation is much higher than that of small machines, and the area is not as large as that of large-scale pipelines. The filling speed is somewhere in between.

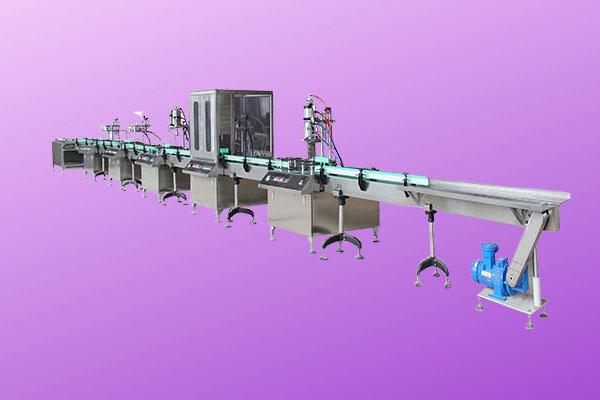

For high output requirements, a fully automatic aerosol filling production line can be selected. This production line consists of a bottle unscrambler table, a fully automatic filling machine, an automatic valve loading machine, an automatic sealing inflator, an automatic weighing, an automatic water detection automatic nozzle machine, an automatic capping machine, an online printer, Box packing composition. At the same time, it is also suitable for all kinds of self-painting, cleaning agents, rust inhibitors, pesticides and other production filling, fast filling speed, large output. Can be customized to meet the requirements of special products and different specifications.

With the development of science and technology and the continuous improvement of people’s living standards, there are more and more aerosol products, and the application fields will continue to expand, and there are still many potential fields to be developed. The equipment for producing such aerosol products includes semi-automatic production equipment and small fully automatic equipment of small enterprises, as well as large-scale assembly line equipment with high output requirements. In general, it supports customized equipment, plant layout, project implementation, comprehensive support for technology, and one-stop nanny service. Engineers can assist customers to build factories and provide technical support for life, eliminating customer worries.