Rust Removing Spray Filling Solution

What is Rust Remover Spray?

Metal products are durable and are indispensable instruments in our life. But the problem of metal rust is also a headache. Now many rust remover, especially the emergence of rust remover spray, help people solve this trouble. Just spray it and erase, you can easily remove rust.

Rust Remover Spray Usage

In addition to its application in daily life, rust remover spray is also widely used in industrial manufacturing, construction, repair engineering, transportation, energy industry and so on, which promise broad market. Like many other spray products, rust removal spray is widely accepted by the market for its convenience.

Rust Removing Spray Filling Solution

To help our customers set up rust remover spray business, we offer 1vs1 technician service including formula suggestions, layout design, equipment using guidance. Some functions can be adjusted on demand.

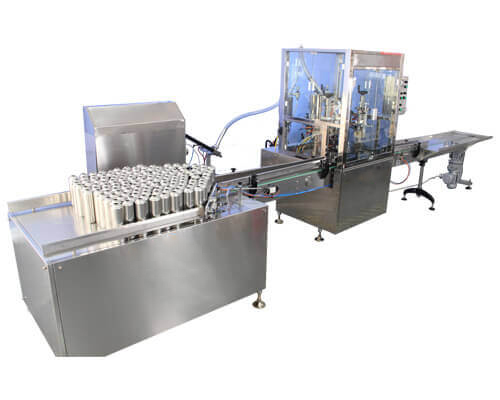

120A Rust Remover Spray Aerosol Filling Machine

There are two sets of main function filling machines in this HDC 120A Aerosol Filling Machine series. It's a basic aerosol filling line that will accomplish simple aerosol filling and sealing. This aerosol assembly line is more popular to the beginner in aerosol production area.

For specific machines, there are two liquid filling machines, valve correcting machines, sealing and gas filling machines. And the filling is organized in a rotary table.

HDC 120A Aerosol Filling Machines are CE verified with branded core mechinery embedded. We use Siemens PLC control and Schneider low voltage component to ensure better stablity and durablity.

Although it's a basic solution to offer backbone aerosol filling functions, we can make it more powerful and flexible by adding bottle arranging machine, valve inserting machine, nozzle pressing machine and capping machine. Functions can be enriched on demand.

| Production capacity: | 1500-2000cans/hour |

|---|---|

| Max liquid volume(ml): | 10-1000ml |

| Max gas volume(ml): | 10-750ml |

| Liquid filling accuracy: | ≤±1% |

| Gas filling accuracy: | ≤±1% |

| Working pressure: | 0.75-0.9Mpa |

| Air consumption: | 3m³/min |

| Applicable aerosol can diameter: | 35-65mm |

| Applicable aerosol can height: | 70-330mm |

| Available valve: | 1”(25.4mm) |

120B Rust Remover Spray Aerosol Filling Machine

The 120B series automatic aerosol filling line includs whole aerosol filling procedure: can arranging, inserting valve, filling and sealing in rotary table, weight checking, leakage detection(water bath), nozzle pressing, cover capping, text printing, carton sealing and strap packing.

All core components is Siemens and Schneider branded, the assembly line is a convenient & stable choice for many aerosol producers. No matter you are experienced or new to the aerosol business, this aerosol line will relase you from the production quality control and give entrepreneur more time to do the marketing job.

It's widely used and applicable to different liquid and gas, including water, oil, paint, foam cleaner, cosmetics... We can also offer filling solutions for medical meterial and food which will meet the hygiene and safety requiements.

| Production capacity: | 2500-3200cans/hour |

|---|---|

| Max liquid volume(ml): | 10-1000ml |

| Max gas volume(ml): | 10-750ml |

| Liquid filling accuracy: | ≤±1% |

| Gas filling accuracy: | ≤±0.03mpa |

| Working pressure: | 0.65-1.0Mpa |

| Air consumption: | 5m³/min |

| Applicable aerosol can diameter: | φ35-φ65 |

| Applicable aerosol can height: | 70-330mm |

| Available valve: | 1〞(25.4mm) |