What are the requirements for filling aerosol cosmetics on the production floor?

Why bag on valve packing is superior to traditional aerosols

October 21, 2019

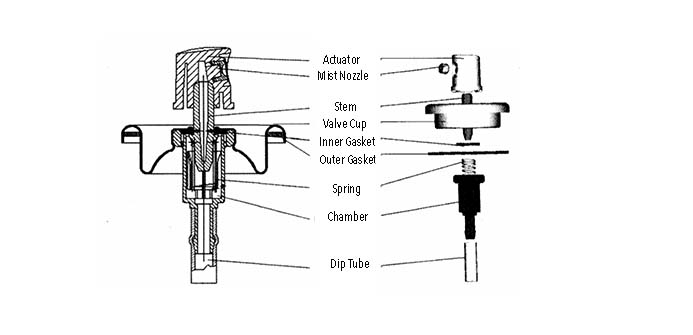

Why Does The Aerosol Valve Leak?

October 29, 2019In recent years, a lot of new brands have been added to the market, but now the market is so competitive, and it is not a simple matter to get better from the market. In order to have better development, we must first ensure that our products are of good quality and strictly control every aspect of processing. In addition to ensuring the quality of raw materials and the technology of filling, the first step in the production of aerosol cosmetics is to ensure a good processing environment.

Under normal circumstances, the cosmetic filling workshop is mainly processed in a clean room. The dust-free workshop is divided into an ordinary dust-free workshop and a GMP 100,000-level workshop. The dust-free workshop mainly excludes particulates, bacteria, harmful air and other pollutants in the air in a certain space, and controls indoor temperature, cleanliness, indoor pressure, airflow velocity and airflow distribution, noise vibration, illumination, and static electricity. Within the requirements, this is a specially designed room. The GMP Class 10 workshop mainly refers to the workshops with cleanliness of GMPC requirements. In a space of one foot, the number of 0.5 micron dust particles allowed to be within 100,000 is higher. When the staff enters the workshop, they must use clean air to clean the dust attached to the clothes according to the corresponding standards and enter the processing room.

The aerosol cosmetic processing plant filling workshop should be clean and tidy, and there should be special cleaning equipment in the area. The work item should be placed in a designated location in the filling area with packaging (cans, valves, nozzles, covers and other items) and registered into the filling shop before filling begins. Check if there is a WIP storage area. Check whether the staff has learned the condition of the production line and whether there are already established standards. The quality control department should check the filling accuracy and error of the in-process product in batches. The filling shop should also regularly check the suitability of the filling equipment and maintain it regularly. Some filling operations will become more complicated due to factors such as smaller batch sizes and weird switches.

The equipment for filling aerosol cosmetics is quite special. Compared with ordinary pastes, liquid cosmetics are much more elaborate. The equipment used is a binary packaging aerosol filling machine. The assembly line of filling lines covers the bottle and sealing. , the process of filling, weighing, water bath testing, buttoning the nozzle, buckle cover, etc. The equipment is highly automated and saves labor. The equipment is driven by air and is safe and reliable.