What are the advantages of semi-automatic aerosol filling machine?

Automotive Care Aerosol Products Collection

July 15, 2021

How to operate the semi-automatic aerosol filling machine?

July 26, 2021Semi-automatic aerosol filling machine is featured with semi-automatic filling process. Compared with the full-automatic aerosol filling machine, when using semi-aotumatic aerosol filling lines, many processes need to be completed manually, which is suitable for small scale production or experimental research.

Aerosol filling machine, according to the different degree of automation, there are different configurations and models. The most common classification is semi-automatic and automatic, the difference is mainly based on the production process, labor needed, price.

Now, we give a brief introduction on the structure and working principle of aerosol. Aerosol refers to the product that combines the contents and the propellant in a pressure vessel equipped with a valve, and can spray out the aerosol contents by the nozzle when the valve is opened. It consists of pressure vessel, contents, valve system, propellant gas, nozzle, etc.

In the production process of aerosol products, appropriate contents (stock solution) are injected into the pressure vessel first, then the valve is sealed tightly, and then the propellant gas is injected into the closed vessel through the valve system, and the nozzle and outer cover are fastened to complete the final product.

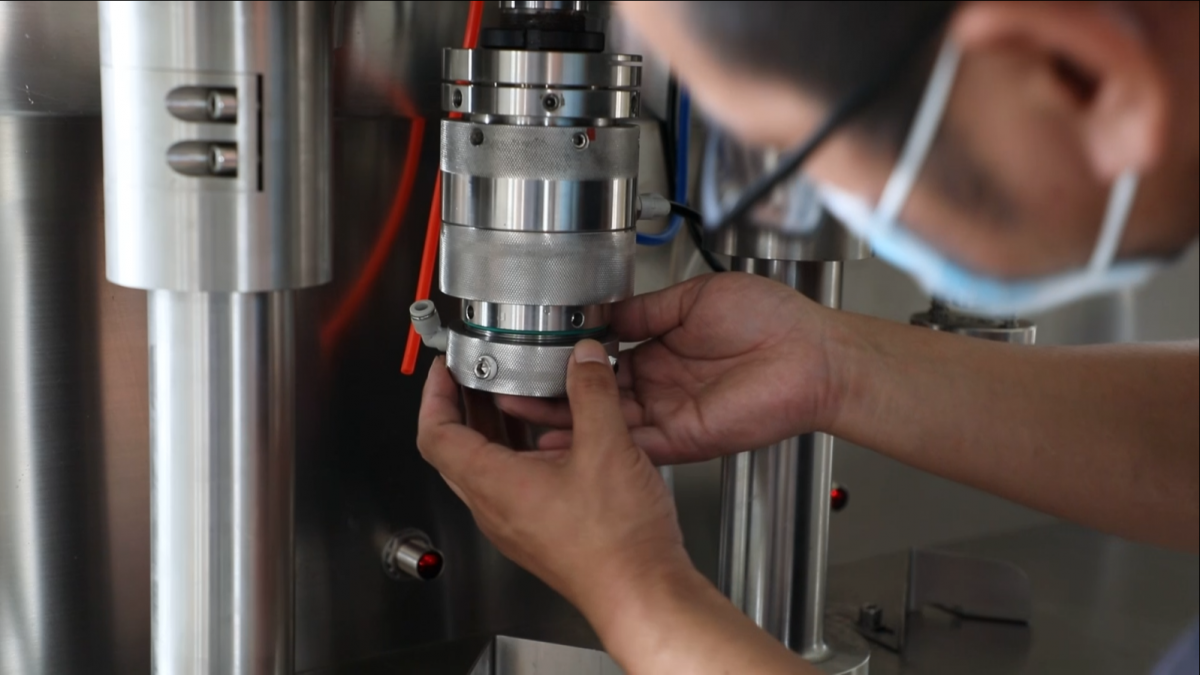

The semi-automatic aerosol filling machine is designed according to its simple production process, which is mainly composed of three important parts: filling machine, sealing machine and gas filling machine. The price is much cheaper than fully automatic equipment.

At present, with the development of science and technology, the machine is more flexible in the production and operation. The whole production process can be completed by 1-2 people. The operation button of the equipment can be inched, linked, on and off, and the manual and automatic filling modes can be freely switched.

Cylinder push bottle instead of manual transmission, workers in the state of continuous production is not easy to fatigue. The machine is equipped with a compressed air storage tank, which makes the air source power more stable. Hand operated adjusting rod, driven by worm, can easily adjust the lifting of equipment. Humanized automatic drop valve design, to avoid the hidden trouble caused by workers’ misoperation.

Can be equipped with protective cover, the machine is more beautiful, the operator is more protected. The air extraction pipeline is reserved for the machine, and the combustible propellant gas can be extracted in time to ensure the whole aerosol workshop.

Semi-automatic aerosol filling machine features:

1. Elaborate design: every part is made according to the requirements of art.

2. Good air tightness: the sealing mouth adopts the guiding sealing, with no air leakage and high sealing quality.

3. Good material: 316L stainless steel, strong corrosion resistance.

4. Metering precision: the filling quantity can be adjusted according to the product demand.

5. Stable performance: branded components, more durable.

6. Simple operation: inching or automatic mode, one person can complete the process.

In the increasingly fierce market competition, product packaging plays an important role for the brand to stand out. Aerosol packaging offers us many advantages, such as easy to use, precise release, avoiding leakage and overflow, clean and sanitary sealing, recyclable and so on, which have been recognized by more and more manufacturers and consumers.

Nowadays, aerosol has been widely used in various fields. Semi automatic aerosol filling machine is a common equipment for new product R&D enterprises, which can not only reduce the investment cost, but also complete the R&D.