How to adjust the automatic aerosol filling machine for first use?

How is BOV filling tech applied to our daily life?

July 27, 2021

Aerosol Filling Machine in Pakistan – New order and shipment

August 5, 2021Automatic aerosol filling machine is the filling equipment for aerosol products. Aerosol is commonly used in our life: sunscreen Spray, medical spray, mosquito killer and so on.

The automatic aerosol filling machine consists of three parts: filling machine, sealing machine and gas filling machine. The equipment is powered by the air compressor without electricity.

1、 Adjust the main engine air supply pressure.

Open the hand slide valve in front of the air source, pull up the pressure regulating knob on the air source, rotate clockwise, and the pressure rises. Rotate counterclockwise and the pressure drops. Adjust to the required pressure (generally 0.6-0.7mpa), and press the pressure regulating knob to lock it.

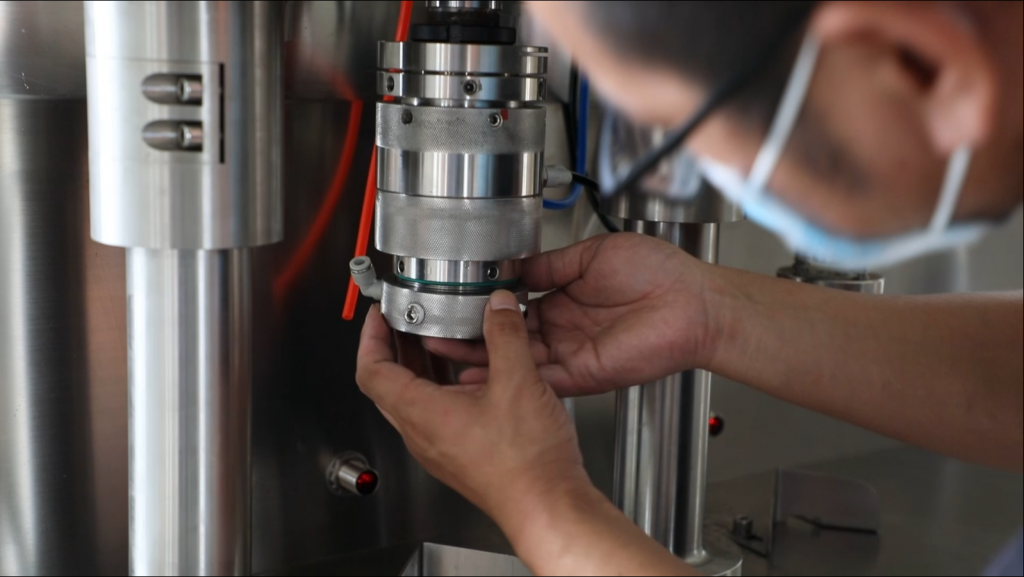

2、 Adjust the sealing diameter and sealing depth

Open the manual slide valve and the sealing knob switch on the panel before the main engine air supply, take a valve and press it into the sealing head with your fingers, step on the foot valve, take out the valve, and measure the outer diameter and height of the sealing. General iron cans are equipped with iron valves, and the sealing outer diameter is controlled at 27.9mm ~ 28.0mm. The sealing height shall be controlled within 5.1mm-5.2mm. First loosen the lock nut on the sealing diameter adjusting screw block, rotate the adjusting screw block counterclockwise to increase the sealing diameter, and rotate the adjusting screw block clockwise to reduce the sealing diameter. If the sealing height needs to be adjusted, loosen the three fastening screws under the sealing head with the hexagon socket first. The right rotation of the rotating block is to increase the sealing height and the left rotation is to reduce the sealing height. After adjusting to the required sealing outer diameter and height, lock the nut( When the diameter of the sealing claw is too large, it is not suitable to adjust the diameter of the sealing claw, so as not to damage the sealing rod when there is a sealing claw, and the diameter of the sealing rod is no longer adjusted.

3、 Adjust the height of the main engine bedplate.

First press the top of the sealing cylinder to make the sealing cylinder go down to the bottom. At this time, the bottom of the sealing cylinder will press the copper top pin on the sealing signal valve. Then place an aerosol tank to be filled in the guide rail directly below the sealing head (Note: the aerosol tank has been sealed for convenient positioning). Loosen the set screws of the guide column in front of the bedplate and the four fastening screws behind the bedplate column. Rotate the lifting handle to adjust the height of the platen so that the sealing mouth can just press the valve of the aerosol tank. When the sealing head presses the valve, it should not be too tight or too loose, so that the tank can just not move up and down. Then tighten the positioning screws of the bedplate guide column and the fastening screws of the bedplate column.

4、 Adjust the position of filling head and inflation head.

Before closing the air source of the main engine, place an aerosol tank under the sealing machine, press the sealing top with your hand to make the sealing head press the aerosol tank and keep the position of the aerosol tank stationary, and then place the aerosol tank in the guide rail to make it close to the aerosol tank under the sealing mouth. Loosen the four nuts fixing the filling head on the bedplate, adjust the position of the filling head so that the filling nozzle is facing the aerosol tank, and then tighten the nuts. Adjust the position of the inflation head in the same way so that the inflation nozzle is facing the valve core position of the valve, and then tighten the nut. Then place an aerosol tank adjacent to the aerosol tank under the inflation head, adjust the positioning handle at the tail of the guide rail to make it just stand against the aerosol tank, and then tighten the nut.

5、 Metering adjustment of liquid filling machine and gas filling machine.

The height of the positioning piston of the metering cylinder can be adjusted by rotating the adjusting knob on the top of the metering cylinder, so as to change the stroke of the metering cylinder piston to change the metering size of filling( Note: before adjustment, close the hand slide valve in front of the air source on the host and wait for the compressed air in the equipment to be drained, otherwise the rotary handle cannot be turned. Adjust the metering from small to large (clockwise is to increase the metering). In the adjustment process, the rotary handle may not continue to rotate after adjusting a certain distance. If the gas metering cylinder is adjusted, it is necessary to push the charging nozzle of the charging head up and discharge a little liquefied gas properly to continue the adjustment; If the liquid metering cylinder is adjusted, a small rod shall be used to push up the white tetrafluoro plug in the liquid filling head. Be careful not to use too much force to avoid damaging the plug. Then, use a container to catch the liquid flowing out during adjustment and metering under the liquid filling head). First adjust the metering to an approximate position for trial filling, and then adjust the metering according to the filling volume until the metering meets the required requirements.

6、 Commissioning of booster pump.

Open the hand slide valve in front of the air source of the booster pump. When the booster pump is idling, the piston will move up and down. Adjust the pressure of the propellant by adjusting the regulating knob of the pressure reducing valve on the air source triplet of the booster pump. Generally, the pressure of the propellant is adjusted to 1.0MPa.