Advantage Analysis of BOV Filling Equipment for Aerosol Cosmetics

What Is Behind The Canned Fresh Air And Canned Pure Oxygen Business?

October 29, 2019

Do you know the difference between aerosols and aerosols?

November 20, 2019In 2017, the market size of China’s cosmetics has accounted for 11.5% of the global market, second only to the US’s 18.5%. China has become the second-largest country in cosmetics use, and the total volume has continued to rise. Among them, the aerosol cosmetic spray products bring the user’s a more extreme experience to the user with the advantages of soft and fine mist, continuous spray at any angle, no secondary pollution, propellant vaporization, and heat absorption, and so on. How is cosmetic filler?

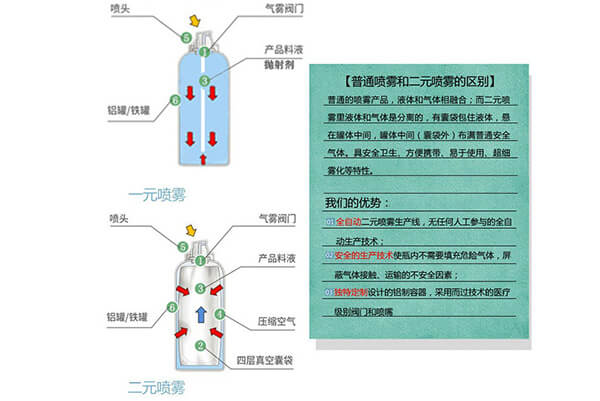

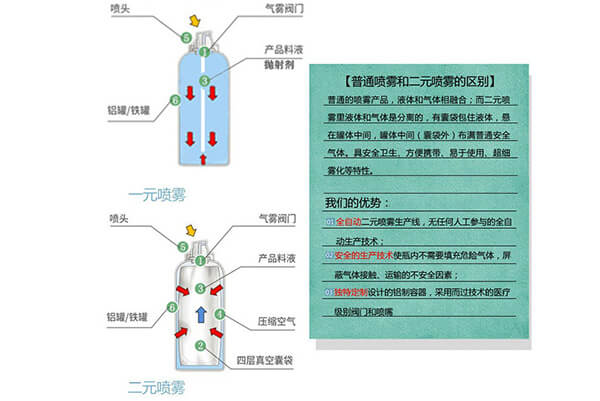

The traditional cosmetic filling method is a one-yuan filling technology. The raw materials and the propellant gas are directly mixed in the aerosol tank. Since the propellant gas is flammable and explosive, the raw materials in the bottle are also highly susceptible to contamination. Filling techniques are becoming more common. Compared with the one-dimensional filling, the liquid and gas in the binary spray are separated, and the bag encloses the liquid, suspended in the middle of the tank, and the propellant gas is outside the bag, which is safer and healthier. Therefore, in the production process of the binary aerosol filling machine, the valve with the bag is first placed in the bottle, the sealing is inflated, the compressed air is filled into the filling, and then the liquid is forced to be filled in the bag… The propellant is also converted into purified compressed air from dimethyl ether, propane, etc. so that the raw material does not corrode the leakage caused by the aerosol can. On the other hand, when the raw materials in the bottle are used, the compressed air in the bottle is not consumed, so the filling can be repeated and reused.

Need to use the product produced by the binary aerosol filling machine:

1. A product that reacts with oxygen and the raw material reacts with oxygen.

2. Products that react with the metal of the can and the raw materials of the product react with the metal on the can.

3, like food, daily chemical industry, this product has high requirements for health level

4, strong acid and alkali are corrosive products on the tank

5, water-based products, can not be connected with liquefied gases

BOV aerosol filling workflow:

1. Filling process: aeration, sealing, forced filling

2. Propellant: Commonly compressed air or nitrogen

Market demand for binary products:

1. Drugs, such as asthma spray, dermatitis spray, etc., which require more North American markets.

2. Foods, such as flavor sprays, are in demand in the Indian market.

3. Beauty, such as hair gel, hair dye, moisturizing water, etc., India and Thailand have more market demand.