Bag On Valve Filling Machine and Process

Bag on valve filling technology is the latest trend of aerosol filling machine technique. We use bag-on-valve filling machine to satisfied the specific need to seperate aerosol content with propellant gas. This so called bag on valve tech helps to make the aerosol products purer and safer. This new aerosol filling technique helped us fixed many unusual filling issues. To understand the bag on valve filling process, we'd like to stress the seperation of aerosol and propellant through the bag. Bag on valve filling technique usually used for those who have high requirements of environmental friendly aerosol products and prone to be corrosion products, such as cosmetic products, aerosol food sprayer products etc.

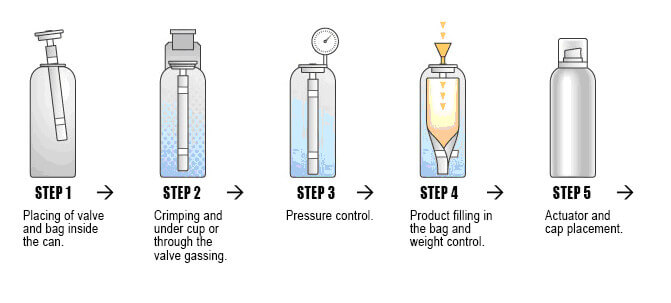

Bag on Valve Filling Process

For the production of BOV aerosol products, the process is featured with the special valve. Firstly, a valve is inserted into the can. The valve is fixed with a composite bag, when filling the aerosol, we will fill the liquid or other raw meterials to the bag while the propellant is filled to the can outside the bag.

With bag on valve, we can seperate aerosol with can and propellant. This helps to prevent further reaction and corrosion.When the comsumer press the nozzle, the aerosol meterial is pressed out and form continuous spray.

The bag on valve filling process is different from normal aerosol filling due to the seperation of aerosol and propellant through the small bag. Although it's a new aerosol filling tech, we are now able to provide our customers professional bag on valve aerosol filling machines, both semi-automatic and full automatic.

Features Of Bag On Valve Aerosol Filling Machines

1.Easy to use: With programable PLC control, our BOV aerosol filling machines are rather simple to operate. You can finish different settings through touch screen(monitor). No basic knowledge needed and anyone can take control of the machine quickly.

2.Safety guarantee: We use Siemens PLC system and Schneider component which give better performance. The machines are designed to be pneumatic driven, no electricity, fire, or other dangerous elements.

Additional Benefits For Manufacturing Your Product With Bag on Valve Technology

1.Dispense the product in any form, such as liquid, gel or cream.

2.Continuously sprayfrom any angle, even upside down.

3.Package your product with a standard actuator in steel or aluminum cans.

4.Complete protection from oxygen exposure, eliminating the need to add preservatives.

5.No chilling effect.