Aerosol Spray Paint Filling Solutions

What is Paint Spray ?

Paint spray is mainly used for paint the funitures, walls or art creation. It enables people to paint something without using brush. A paint spray will contain three main parts:can, valve and propellant. With the effect of high pressure filling, we can easily spray out the paint although it's viscous liquid.

Paint Spray Market and Potential

The market of paint spray is anticipated to arise with the technology development. Home funishing, building construction, automobile coating and other expanding usage of spray paint gives us positive signals.

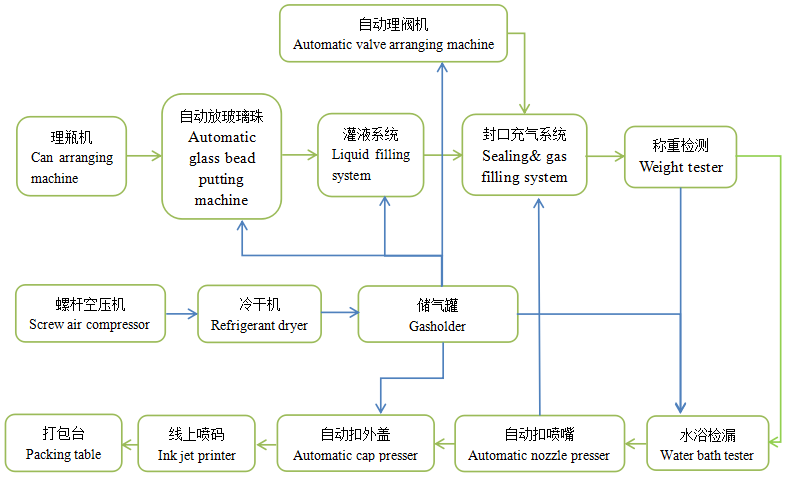

Work Flow of Spray Paint Filling

Aerosol Spray Paint Filling Solutions

100A 3 in 1 Aerosol Filling Machine for Spray Paint Production

For XLD 100A Paint Spray filling machine series, there are specific machines covering all the aerosol filling needs: liquid filler, valve inserter, sealer and gas filler(propellant). We use auto converyor and pusher to make bottle moving ahead without manual help.

This aerosol machine can work in two mode, you many choose manual intermittent filling or auto intermittent filling. And the interval time can be varied according to your adjustment.

As other fundamental aerosol machines, the 100A is extendable with other aerosol machines like can arranger, nozzle presser, capping machine and can printer. Other functions can also be customized on demand.

This aerosol machine can be applied to various aerosol products, such as personal care aerosols, food aerosols, pharmaceutical aerosols, car-care products and etc.

| Production capacity: | 4000-5000cans/day |

|---|---|

| Max liquid volume(ml): | 20ml.50ml,100ml,300ml,500ml,1000ml |

| Max gas volume(ml): | 20ml.50ml,100ml,200ml,400ml,500ml |

| Liquid filling accuracy: | ≤±1% |

| Gas filling accuracy: | ≤±1% |

| Working pressure: | 0.65-1.0Mpa |

| Air consumption: | 0.8(m3/min) |

| Applicable aerosol can diameter: | 35-65mm |

| Applicable aerosol can height: | 70-330mm |

| Available valve: | 1”(25.4mm) |

120B Full Automatic Aerosol Filling Machine for Spray Paint Production

The 120B series automatic aerosol filling line includs whole aerosol filling procedure: can arranging, inserting valve, filling and sealing in rotary table, weight checking, leakage detection(water bath), nozzle pressing, cover capping, text printing, carton sealing and strap packing.

All core components is Siemens and Schneider branded, the assembly line is a convenient & stable choice for many aerosol producers. No matter you are experienced or new to the aerosol business, this aerosol line will relase you from the production quality control and give entrepreneur more time to do the marketing job.

It's widely used and applicable to different liquid and gas, including water, oil, paint, foam cleaner, cosmetics... We can also offer filling solutions for medical meterial and food which will meet the hygiene and safety requiements.

| Production capacity: | 2400-3600 cans/hr |

|---|---|

| Max liquid volume(ml): | 50-560ml |

| Max gas volume(ml): | 50-500ml(liquid) |

| Liquid filling accuracy: | ≤±1% |

| Gas filling accuracy: | ≤±1% |

| Working pressure: | 0.6-1.0mpa |

| Air consumption: | 5m³/min |

| Applicable aerosol can diameter: | φ35-φ65 |

| Applicable aerosol can height: | 70-330mm |

| Available valve: | 1〞(25.4mm) |