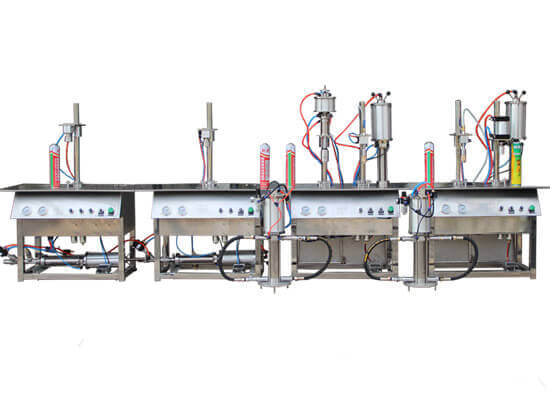

HDC-100CS Semi Automatic Aerosol Filling Equipment - Introduction:

This semi automatic aerosol filling equipment consist of 7 machines, one set of semi-automatic liquid filling machine for MDI, one set liquid filling machine for PPG, valve crimping, one set gas filling machine for DME, one set gas filling machine for LPG, one set sealing machine for gun type PU foam and material shaker.

100CS semi automatic aerosol filling machine can flexible design for 1-6 working table. It absorbs foreign advanced technology, no discharging without filling. It is sealing with high quality for adopting oriented-sealing. The way of the oriented inflation in the charging end is accurate and efficient with minimal gas consumption. This machine is in advanced level of the same industry at present. It have been exported to europe, america, africa, southeast asia etc.

Technical Parameters:

(1) Liquid filling device

Outline of host (L*W*H) (mm)

Bench of metering cylinder (L*W*H) (mm)

Height of aerosol can (mm)

Diameter of aerosol can (mm)

Max. liquid fill each time (ml)

Capacity (cans/hr)

Max. gas consumption (L/min)

970*510*1400

700*500*250

≤450

Customizable

530

500-1000

500

(2) Closing device

Outline of host (L*W*H) (mm)

Height of aerosol can (mm)

Diameter of aerosol can (mm)

Size of valve (inch)

Closing contact height (mm)

Capacity (cans/hr)

Max. gas consumption (L/min)

970*510*1400

≤450

Customizable

1

0~10 adjustable

800~1200

300

(3) Aerating device

Outline of host (L*W*H) (mm)

Height of aerosol can (mm)

Diameter of aerosol can (mm)

Max. gas fill each time (ml)

Capacity (cans/hr)

Max. gas consumption (L/min)

970*510*1500

120~320

Customizable

320

500-1000

300

(4) Capping device

Outline (L*W*H) (mm)

Height of aerosol can (mm)

Diameter of aerosol can (mm)

Capacity (cans/hr)

Max. gas consumption (L/min)

970*510*1400

≤450

≤200

800~1200

100

(5) Vibrating grid

Outline (L*W*H) (mm)

Max. gas consumption (L/min)

Max. load (kg)

800*400*900

300

80

Technical Information: