Olive Oil Spray Filling Solutions

Marketing of Olive Oil Spray

There are more than thousands of olive oil brands. As the biggest producing area of olive oil in the world, Spain is also the biggest consumption country of it, and even needs to import olive oil.

As a big trading nation, Italy possesses the largest number of olive oil brands, and mainly exports the imported goods after processing. The Aegean region(Greece, Turkey), the orthodox birthplace of olive, is one of the regions that have the greatest and largest number of olive, which is mainly exported to European and American developed countries.

Apart from EU, America is the biggest consumption and exporting country of olive oil. Although it doesn’t produce olive oil, it has many famous brands, mainly imported from Greece, Turkey, Spain and Tunisia.

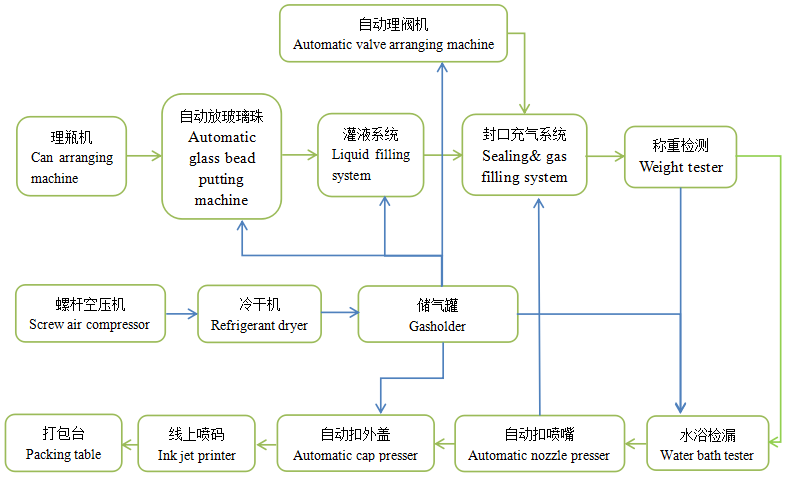

Working Flow of Olive Oil Spray Production

Olive Oil Spray Filling Solutions

Just follow our formula, and you can start production with guidance of technician. It only needs one or two people to finish flow line production, not limited by degree of education and production environment.

100A 3 in 1 Aerosol Filling Machine for Olive Oil Spray Production

This machine, whose liquid filling, sealing and gas filling heads are fixed in one working table, needs three people to do linear transmission to finish filling and production. It can work more stably and safely with a booster pump.

The sealing machine adopts advanced structural technology. And its crimping head adopts oriented-sealing which can guarantee high-quality and high-speed sealing, and it is easy to operate, adjust and maintain. This machine consists of two air cylinders. It uses lower cylinder (clamping cylinder) to drive crimping head to compress aerosol valve, and finishes sealing by upper cylinder. And this machine is exclusively used in internal-swelling sealing for international one-inch aerosol valve.

Applicable products: food industry such as linseed oil and cake baking oil; daily-use chemical industry such as air freshener and pesticide spray; industrial products such as spray paint, release agent and antitrust agent; and cosmetic and pharmaceuticals industry such as Yunnan Baiyao spray, gall aerosol and lidocaine aerosol. This machine is used to fill international one-inch tinplate and aluminum aerosol cans, not limited by the height and diameter of the can. The machine can be adjusted according to the actual situation.

| Production capacity: | 3000-5000 cans/hr |

|---|---|

| Max liquid volume(ml): | 50ml-750ml |

| Max gas volume(mpa): | 0.2-1.5mpa |

| Liquid filling accuracy: | ≤±1% |

| Gas filling accuracy: | ≤±0.03 mpa |

| Compressed air pressure: | 0.65-1.0 Mpa |

| Air consumption: | 1.0(m3/min) |

| Applicable aerosol can diameter: | 35-65mm |

| Applicable aerosol can height: | 70-330mm |

| Equipment dimension: | 1000*600*1500mm 110kg |

| Available valve: | 1”(25.4mm) |

120B Full Automatic Aerosol Filling Machine for Olive Oil Spray Production

120B Automatic spray filling line has adopted foreign advanced technology. With the working principle of piston, its liquid filling system is suitable for many viscous liquids. The pharmaceuticals industry all adopt sanitary pipe fitting. And its crimping head adopts oriented-sealing which can guarantee high-quality. Likewise, with the oriented gas filling, the gas filling machine can be more accurate, efficient and reduce gas consumption. This machine has a high production efficiency. It is safe, stable and easy to operate and maintain. Besides, its main technical index has already reached the level of the same kind of product at abroad. This machine is in the leading level of this industry, and has been sold to Europe, America, Africa and Southeast Asia.

It is mainly used in many industries: food industry such as linseed oil and cake baking oil; daily-use chemical industry such as air freshener and pesticide spray; industrial products such as spray paint, release agent and antitrust agent; and cosmetic and pharmaceuticals industry such as Yunnan Baiyao spray, gall aerosol and lidocaine aerosol. This machine is suitable for both tinplate and aluminum can, not limited by the material of container. It applies to one-inch spray valve. The whole machine adopts rotating-disk transmission principle, which can produce 30-50 cans per minute to meet the need of manufacturer.

| Production capacity: | 1800-2500 cans/hr |

|---|---|

| Max liquid volume(ml): | 50ml-750ml |

| Max gas volume(mpa): | 0.2-1.5mpa |

| Liquid filling accuracy: | ≤±1% |

| Gas filling accuracy: | ≤±0.03 mpa |

| Compressed air pressure: | 0.65-1.0 Mpa |

| Air consumption: | 5m³/min |

| Applicable aerosol can diameter: | 35-65mm |

| Applicable aerosol can height: | 70-330mm |

| Equipment dimension: | 1000*600*1500mm 110kg |

| Available valve: | 1”(25.4mm) |