4 Tips You Should Know Using DME As The Aerosol Propellant

TOP 5 THINGS TO KNOW ABOUT LIQUID FILLING EQUIPMENT

July 4, 2019

Why Does The Aerosol Valve Leak?

August 30, 2019DME(Dimethyl Ether) was massively produced since 1966. Western Germany company Union Kraftstoft Gmbh produced high purity DME to apply in the hair spray industry under the request of Netherlands company Aerofako BV.

Until 1970, DME makes up about 20%, annual consumption 10,000 tons, in Europe. Japan started DME production after 1979 with annual production 6,500 tons. As a fast-developing part of the aerosol industry, USA Dupon company started DME production until 1981.

DME Properties

It is a colorless and odorless inert gas.

Molecular Formula: CH3OCH3

Molecular Weight: 46.07

Boiling Point: -24.9℃

Explosion Limit: 3.4~18%

Self-ignition Point: 350℃

Burning Heat: 6,900kcal/kg

Flashing Point: -41℃

Viscosity: 0.0102CP(20℃)

With certain solvent enhancer, 6% alcohol for example, DME and water can inter-solute with each other under any ratio.

| Temperature | Vapor Pressure(Mpa) | Liquid Density(kg/m³) |

| -20 ℃ | 0.140 | |

| 10 ℃ | 0.240 | |

| 21.1 ℃ | 0.417 | 659.96 |

| 32.2 ℃ | 0.520 | 627.92 |

| 43.3 ℃ | 0.861 | 618.31 |

| 51.1 ℃ | 1.172 | 603.90 |

Inter-solubility

With certain solvent enhancer, 6% alcohol for example, DME and water can inter-solute with each other under any ratio.

Once its K-B value is 60, it has perfect solubility. It can inter-solute with LPG, CFCS, alcohol, ketone, ether, ect.

DME Applications

1. Insecticide Spray

DME is widely applied in the insecticide spray. It can be dissolved into a water well and the price is moderate. The water-based formula using DME can create a comfortable environment. Compared to solvent-based formula, the water-based formula has the advantages of moderate price and environment-friendly, determining the trend of water-based insecticide replacing oil-based insecticide.

Many active elements used in the oil-based insecticide spray are easily resolved in water, which limits the product shelf life and bug-killing performance.

Many research technicians are working on the chemicals suitable for water-based insecticide spray, enabling the bug-killing performance of the water-based insecticide spray is as good as the oil-based type.

The active elements in the water-based insecticide spray basically do not dilute into water. So, the key to producing water-based insecticide spray is to solve the emulsification or solution of the active elements, to spread evenly the active elements into the water, and store stably for a long time.

The emulsifying agent is the key to emulsification. Usually, it is preferred to choose W/O type with HLB value at 3~5, like Span series, Tween series, ect.

2. Room Air Freshener

The strong solubility of DME enables it to dissolve 30%(W/W&) into water. And it can reach out the limit to inter-solute with water at any ratio with adding over 6% alcohol.

Use some emulsifying agent to emulsify fragrance essence into alcohol, and then water phase to form a stable single phase.

3. Hair Spray

Alcohol was used as the solvent in the hair spray formula in the past time.

It has shortcomings.

On the one hand, LPG is the propellant gas used, which results in high VOC emission.

On the other hand, high concentration alcohol possibly damages the hair, causing hair broken, and splitting.

Therefore, formula technicians started to develop non-alcohol or less-alcohol hair spray.

DME soon became the alternative propellant gas largely used in hair spray products because of its perfect dilution.

4. Spray Paint

There are some shortcomings using less-dilution propellant gases like LPG and CFC.

It may produce foam during usage. It may result in the poor paint surface.

DME application in the spray paint industry not only solved the above disadvantages, but also formed perfect spray effect, with fine and even droplets and moderate spraying force.

Problems Needing Attention for DME as The Propellant Gas

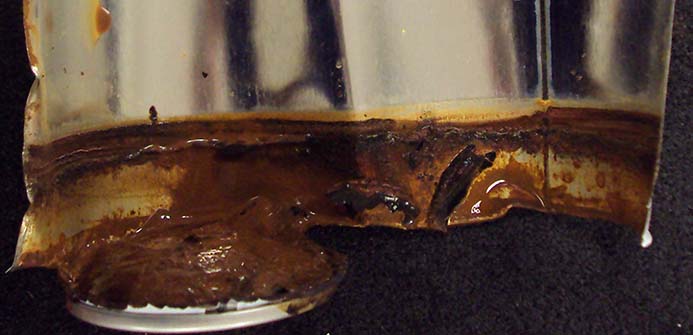

1. Anti-Corrosion

Aerosol corrosion covers chemical corrosion and electrochemical corrosion. Every component should be collected with full attention.

As it comes to DME as the propellant gas, it needs to take precautions against the corrosion of the package with the water and DME.

So, the water has to be deionized. And if possible, vacuum sucks the air in the can top space. Adjust the product PH value at 7~10. Add anti-corrosion agent like sodium benzoate.

2.Safety

DME is a flammable gas.

The formula post flammability is adjustable because it can highly inter-dissolve with water. It can be reduced to poor-flammable or non-flammable.

3. Valve and sealer

The valve cup will contact with DME. DME’s unique solvent property may corrode the valve cup or the lacquer coating, especially when there is water or/and alcohol.

This should be taken consideration especially when DME is considered as the propellant gas.

Besides, some sealers may be problematic due to DME’s perfect disolulity. The sealer expansion ratio is preferred 5%-15% for 72 hours. If the expansion ratio is too much, the leakage might be a big problem as it comes to DME.

4. Manufacturing, storage and transportation

DME is actually stable even though it is a ether product.

It was tested to mix pure DME and other materials under 40℃ for 6 months, and there was no peroxide produced.

It was tested to mix pure DME and other materials under 40℃ for 6 months, and there was no peroxide produced.

Even so, we still pay attention to the safety in manufacturing, storage and transportation.

Electrical appliances must be EX-proof; DME must be stored in cool condition with good ventilation; do not hit and drop the aerosol can during transportation; do not stay close to the fire.